A Cast In heater is a specialized tool used to heat up things in Factories and other industrial places. That’s because it is achieved by essentially putting electric heater heating element right into a piece of material, often metal or plastic. This way, heat goes straight to where it’s needed, which makes this little gizmo super efficient. Cast-in heaters can do all sorts of things, such as keep a materials warm so they flow better or help machines operate at the temperatures that are just right. At Yidu, we ensure our cast in heaters are designed to be tough and dependable so you know they’ll work and last. People who work with them know how they save energy and keep everything cold just right. How does a cast in heater work? Inside the heater, there are special wires known as heating elements. These wires get hot when you flick on the electricity. Unlike standard heaters that are created as a component and then must be installed, cast in heaters are installed into the product. Embedded heaters in the mold can heat it up so that plastic is more malleable, for example if a manufacturer is making plastic parts. That can help avoid issues, such as the material becoming too hard to mold. The heat operates from the inside out, so everything warms evenly. That means there are no cold spots without heat. Factory people eat this up because it makes their lives easier. And cast-in heaters can do very precise heat control, and precision matters a lot in many industrial uses. One of the cool things about them is that they are relatively easy to make in different shapes and sizes

Every now and then, cast in heaters will have problems. One of the most frequent issues is when they cease to heat correctly. This could occur due to normal wear and tear or perhaps a broken electrical connection. If this occurs, the first thing to examine is the power source. Ensure everything is connected right. If the cables appear to be in good shape and there’s power going through them, it is possible that the heating element has gone bad. When that happens, either make good old contact with Yidu for a replacement part. Another issue could be overheating. If a cast in heater overheats, it can do damage to the machinery in which it is installed. This can be repaired by altering the temperature or adding more insulation to stop the heat loss. You’ve also got to maintain it if you want the drug store brand of confidence, which is super important. By spending a few minutes eyeballing and cleaning the heaters, you can nip that in the bud before it becomes an issue. Here at Yidu, we would certainly tell our customers to be aware of their heaters and to make sure they are running at an appropriate temperature. The element in electric heater should be compatible with the processed materials. Skimping on a heater that isn’t designed for specific jobs could result in even more issues further down the road

What’s more making connections with suppliers can be extremely beneficial. If you are a customer of a supplier for many years, it may offer you better prices for larger quantities. They may also be more inclined to assist you if you desire something specific. And if you work with a well known supplier like Yidu ceramic element heater, they often provide tailored solutions according to your requirements, which is ideal since you can get precisely what you want

There are good reasons to consider custom cast in heaters when you need a heating solution. One of the biggest benefits is that these heaters can be customized to fit your needs. Custom ceramic for heating elements options. Unlike ordinary heaters, custom ones let you select out which size, shape and features are going to work best for your business. This makes sure our heaters fit your machine or production line perfectly

Cast in Heating Technologies can significantly improve your industrial operations. To begin with, let’s get acquainted with what cast in heating element of an electric heater are. Such heaters are housed within the apparatuses and introduce hit at field locations where required as such. This is an efficient form of heating, as it cuts down on the time and amount of energy it takes to heat up the entire space. Since thermal cast in heaters can accelerate the speed of production, businesses will save money and increase output

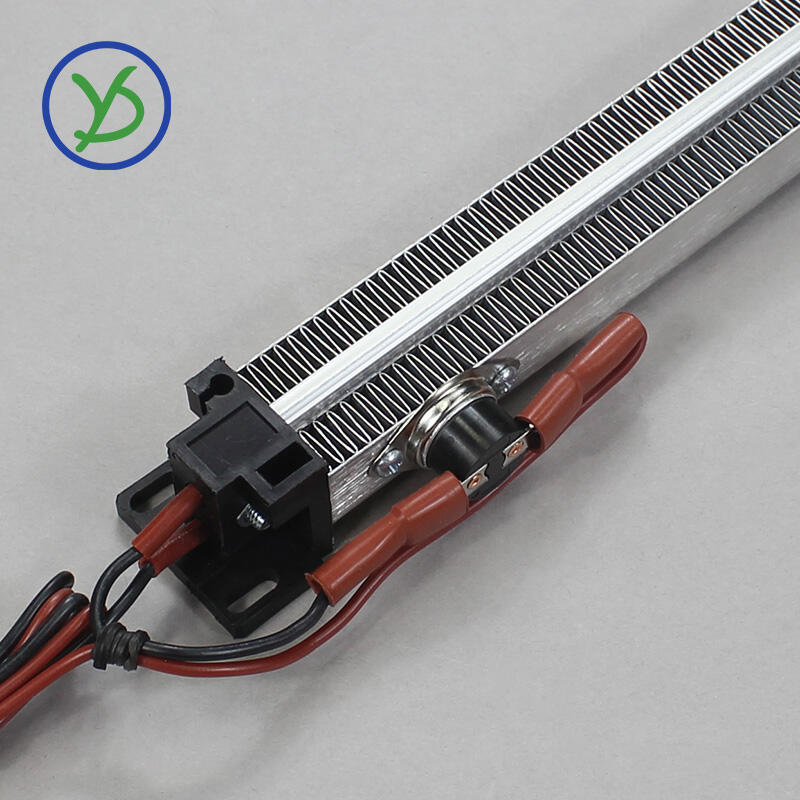

For more than Cast in heater, we've been devoted to the research and production of PTC products, which integrate manufacturing distribution, retail, and manufacturing to create a seamless domestic as well as international, offline and online business model. As a pioneer in the PTC component market we believe in the concept of hand-work. We are focused on technological advancements and develop each product to meet diverse heating requirements of various industrial sectors.

As opposed to traditional heating elements our products are based on PTC heating technology offering high thermal conversion efficiency and a temperature control system that is automatic that lasts for more than 10 000 hours The surface of the heater doesn't display the "red-hot" phenomenon thereby reducing fire hazards and ensuring safety and environmental friendliness which is in accordance with Cast in heater Our designs are user-friendly and adaptable in terms of the power voltage size and so on

Our products are of Cast in heater, we have a good reputation, and we provide a thorough and prompt after-sales assistance as well as prices that are extremely competitive. We satisfy the demands of the market through providing quality, reliable and durable products. Apart from product development and research, our firm will also work to improve service quality in order to please customers. We believe that by continually improving our capabilities and competitiveness on the marketplace, we will prosper and earn more loyalty and trust from our customers.

Our products are commonly used in auxiliary heating systems for air conditioners, power battery heating systems, energy efficient vehicles, Cast in heater for household appliances such as beauty and haircare equipment and medical heating fields. Our experts will design and develop solutions that meet your voltage, power and dimension requirements.